Metal roofing cutters are specialized tools designed to make clean, precise cuts in metal roofing materials. They allow users to cut through metal sheets efficiently while minimizing damage to the material and ensuring a proper fit. These cutters come in various forms, such as hand shears, powered shears, and saws, each suited for different thicknesses and types of metal.

Choosing the right metal roofing cutter depends on factors like the thickness of the metal, the type of cut required, and the scale of the project. Professionals and DIYers alike benefit from using the appropriate cutter to maintain the roofing’s integrity and improve installation speed.

Understanding the capabilities and limitations of each metal roofing cutter helps in making an informed purchase and achieving the best results. This knowledge is essential for anyone working with metal roofing materials.

Types of Metal Roofing Cutters

Metal roofing cutters vary by power source and cutting mechanism, each suited for specific tasks and materials. They differ in precision, speed, and the effort required, making some better for large projects and others ideal for detailed work.

Manual Metal Shears

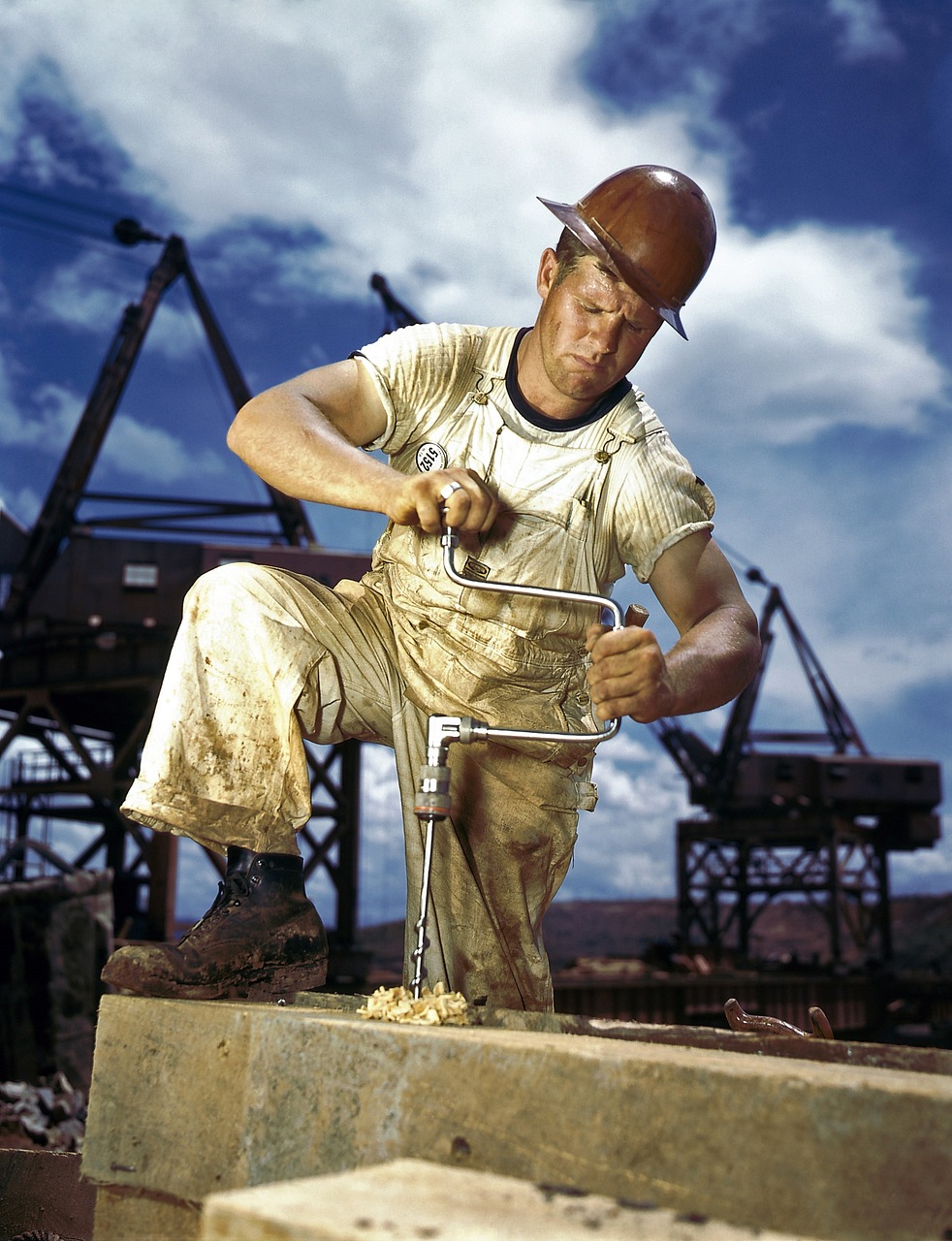

Manual metal shears are handheld tools designed for cutting thin sheets of metal roofing. They operate with scissor-like blades and require physical force to close and slice through the metal.

These shears are best for straight cuts and trimming small sections. They provide good control but can be tiring during extended use. Their cutting capacity usually ranges up to 18-gauge steel or aluminum.

Manual shears are affordable, lightweight, and require no power source. They are useful for quick, simple cuts on smaller projects or touch-ups. However, they are less efficient for thick metals or large-volume jobs.

Electric Metal Roofing Cutters

Electric metal roofing cutters use a motor to power a blade or cutting wheel, allowing faster and more precise cuts. They reduce physical strain and increase productivity compared to manual options.

These tools are versatile, handling thicker gauge metals with ease. They typically feature adjustable speed controls for different materials and cut types. Corded and cordless models exist to suit job site mobility.

Electric cutters are suitable for contractors working on extensive roofing projects. They require electricity or battery power and tend to be heavier. Safety features like blade guards are standard to prevent accidents.

Nibblers

Nibblers cut metal by rapidly punching small bits out of the sheet, leaving a clean, burr-free edge. This method minimizes distortion and is ideal for intricate shapes and curves.

They come in manual, electric, and pneumatic forms, with electric nibblers being common for roofing. The cutting speed is moderate, and they generally handle metal thicknesses up to 16 gauge.

Nibblers excel in detailed work where precision is key. They produce less noise and vibration than saws, making them more comfortable for extended use. However, they are slower on straight cuts compared to shears or saws.

Circular Saws for Metal Roofing

Circular saws equipped with special blades can cut metal roofing sheets quickly and accurately. The blades are designed to reduce heat buildup and prolong service life.

These saws are powerful and handle thick materials efficiently. They are best for long, straight cuts but require careful handling to avoid jagged edges or warping the metal.

Operators must use proper blades specified for metal and wear protective gear. Circular saws are suited for experienced users and large-scale jobs where speed is essential. They typically require a power source and generate noise and dust.

Choosing the Right Metal Roofing Cutter

Selecting a metal roofing cutter requires attention to the tool’s cutting accuracy, safety protocols, and build quality. These factors directly affect efficiency and user experience.

Cutting Performance and Precision

Cutting performance depends largely on the blade type and motor power. Shears with carbide-tipped blades can handle thicker metals cleanly, reducing jagged edges. A cutter designed for precise straight or curved cuts helps maintain the roof’s integrity.

Electric metal cutters usually offer consistent speed control, improving accuracy. Manual cutters suit lighter, thinner sheets but may cause fatigue with prolonged use. Checking the maximum metal thickness rating ensures the tool matches the roofing project needs.

Safety Features

Safety features are essential to prevent injuries during cutting operations. Look for cutters with blade guards to shield the operator’s hands from debris and sharp edges. Automatic shut-off or brake systems can stop the blade quickly after use.

Non-slip grips reduce the chance of slipping, while insulated handles protect against electric shock in powered models. Safety certifications, such as OSHA or CE compliance, indicate reliable design standards.

Durability and Maintenance

A metal roofing cutter must withstand rough job site conditions. High-quality steel or aluminum alloy construction increases tool longevity and resists corrosion. Removable and replaceable blades simplify maintenance and extend cutter life.

Regular cleaning of the blade and lubrication of moving parts prevent rust and mechanical wear. A storage case or cover aids in keeping the cutter safe from dust and moisture when not in use.

Leave a Reply